Food Tech

Smart Factory

Smart Factory

eunha FISHERIES is preparing to set up a smart factory that

achieves total optimization by connecting the data on the

pre- and post-processing beyond the production automation.

achieves total optimization by connecting the data on the

pre- and post-processing beyond the production automation.

Machine

Learning

Learning

We have established and upgraded MES and

ERP production/management system, ultimately

aiming to maximize production efficiency

through AI machine learning

ERP production/management system, ultimately

aiming to maximize production efficiency

through AI machine learning

Major Facilities

High Pressure Processing

Water is used to create a high pressure-environment that eliminates harmful micro-organisms (food poisoning bacteria, etc.)

Modified Atmosphere Packaging

Optimal mixtures of gases such as oxygen and nitrogen, suited to each product, are used to maintain the freshness of the product as long as possible.

Moisture hot-air oven

Moist heat is used to minimize the loss of the meat’s juice and to maintain the food’s distinct flavor.

Thermoforming vacuum packing machine

The custom modular structure enables molded packaging optimized for each product.

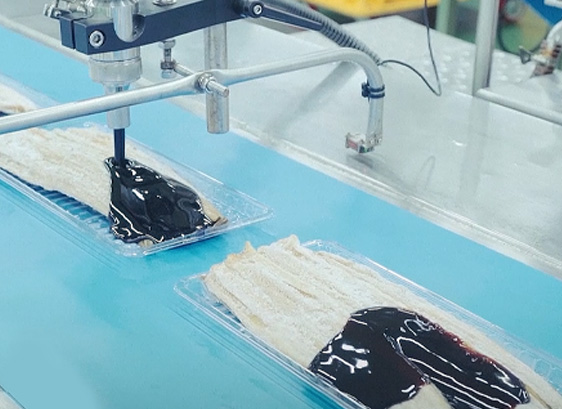

Sauce automatic filling machine

Uniform sauce can be put in according to the set value.

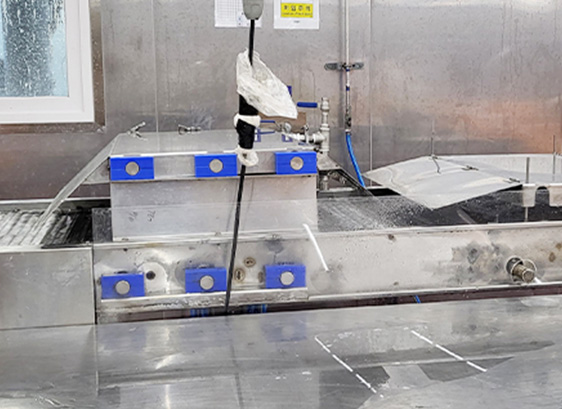

Automatic skate washing machine

It cleans mucus and foreign substances on raw skate.

High Speed Slicer

Mass slicing operations of identical forms are possible

Sanitary disinfection equipment

We continue to invest in hygiene management facilities such as knife and cutting board sterilizer, boots and apron dryer, and large-capacity sterilization washer.